Introduction

Unlocking Comfort: Exploring the Best Hydronic Radiant Floor Heating Systems- is a most common topic. In the pursuit of comfortable living spaces, hydronic radiant floor heating systems stand out as a top choice for their efficiency, even heating, and long-term cost-effectiveness. These systems use heated water circulated through pipes beneath the floor to warm the room, offering a luxurious warmth that surpasses traditional forced-air systems. In this article, we delve into the best hydronic radiant floor heating systems, examining their features, and benefits, and analyzing top contenders in the market.

Understanding Hydronic Radiant Floor Heating

Hydronic radiant floor heating operates on a simple principle: warm water is circulated through a network of pipes installed beneath the floor surface. This heat is then emitted evenly, warming the entire room from the ground up. Compared to forced-air systems, which rely on blowing heated air from vents, hydronic systems offer superior comfort by eliminating drafts and maintaining consistent temperatures.

Key Features to Consider:

When selecting a hydronic radiant floor heating system, several key features should be taken into account:

Energy Efficiency

Look for systems with high-efficiency boilers or heat pumps to minimize energy consumption and reduce heating costs.

Even Heat Distribution

Opt for systems that ensure uniform heat distribution across the floor surface, avoiding hot spots and cold zones.

Compatibility with Flooring Types

Consider systems that are compatible with various flooring materials, including tile, hardwood, laminate, and carpet.

Smart Controls

Integration with smart thermostats and zoning capabilities allows for precise temperature control and energy savings.

Reliability and Warranty

Choose systems from reputable manufacturers with a track record of reliability and comprehensive warranty coverage.

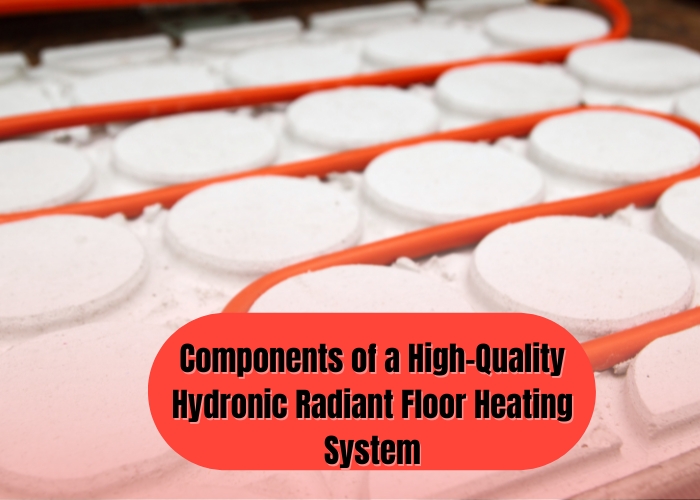

Here is an expanded section on the components of a high-quality hydronic radiant floor heating system:

Components of a High-Quality Hydronic Radiant Floor Heating System

The quality and performance of a hydronic radiant floor heating system depend on the components used. Here are the key components that make up a high-quality system:

Tubing Material

The tubing is the backbone of the system, responsible for circulating the heated water throughout the floors. The most common tubing materials used in hydronic radiant floor heating systems are:

PEX (Cross-linked Polyethylene)

PEX tubing is flexible, durable, and resistant to corrosion and scaling. It’s one of the most popular choices for radiant floor heating systems due to its ease of installation and long lifespan.

PERT (Polyethylene Raised Temperature)

Similar to PEX, PERT tubing is made from high-density polyethylene but with a slightly different manufacturing process. It offers excellent heat resistance and strength.

WIRSBO (Polybutylene)

WIRSBO tubing, made from polybutylene, is another option known for its flexibility and resistance to freezing and corrosion.

The tubing size and layout pattern depend on the specific system design and heat load requirements.

Manifolds and Controls

Manifolds are the hub of the hydronic radiant floor heating system, distributing the heated water to the various tubing loops and controlling the flow. High-quality manifolds are typically made from durable materials like brass or stainless steel and feature precise balancing valves for optimal heat distribution.

Controls, such as thermostats and zone controllers, allow you to regulate the temperature in different areas or zones of the building, providing efficient and comfortable heating.

Boiler or Water Heater

The heat source for the system can be either a dedicated boiler or a high-efficiency water heater. Boilers are designed specifically for hydronic heating systems and can run on various fuel sources, such as natural gas, propane, or electricity. Water heaters with high thermal output can also be used in some cases, especially for smaller installations.

Pumps and Circulators

Pumps and circulators are responsible for moving the heated water through the tubing loops and back to the heat source. High-quality pumps are energy-efficient and designed to provide the right flow rate and pressure for the system’s requirements.

Expansion Tanks and Other Accessories

Expansion tanks are essential components that accommodate the thermal expansion of the water as it heats up, preventing excessive pressure buildup in the system. Other accessories may include air separators, pressure relief valves, and chemical treatment systems to maintain water quality and prevent corrosion or scaling.

By selecting high-quality components from reputable manufacturers and ensuring proper system design and installation, you can expect your hydronic radiant floor heating system to provide efficient, comfortable, and long-lasting heating performance.

Top Contenders in the Market

Several manufacturers lead the way in producing high-quality hydronic radiant floor heating systems. Let’s analyze some of the top contenders:

Uponor Wirsbo:

Known for their innovative PEX piping systems, Uponor offers a range of hydronic radiant floor heating solutions. Their products feature durable materials, easy installation, and compatibility with various floor coverings. Moreover, Uponor’s ProPEX expansion fittings ensure leak-free connections, enhancing system reliability.

Warmboard:

Warmboard stands out for its patented plywood panels with embedded aluminum tubing, designed for efficient heat transfer. These panels provide excellent thermal conductivity, resulting in quick response times and energy savings. Warmboard’s system is also compatible with different floor finishes, offering flexibility in design.

Radiantec:

With a focus on simplicity and affordability, Radiantec offers DIY-friendly hydronic radiant floor heating kits. These packages include all necessary components for installation, making them accessible to homeowners looking to retrofit their existing floors. Radiantec’s systems are praised for their reliability and performance, backed by extensive customer support.

Rehau Raupanel:

Rehau’s Raupanel system features pre-fabricated panels with integrated tubing, simplifying the installation process. These panels can be quickly laid over existing subfloors, reducing labor costs and minimizing disruption during construction. Additionally, Rehau offers advanced control options, allowing users to customize heating schedules and monitor energy usage.

Here are the expanded sections on installation considerations and operating/maintaining a hydronic radiant floor heating system:

Installation Considerations:

Proper installation is crucial for the optimal performance and longevity of a hydronic radiant floor heating system. Here are some key installation considerations:

Site Preparation and Floor Construction:

Before installing the tubing, the site must be prepared correctly. This may involve demolition, leveling the subfloor, and ensuring adequate insulation beneath the tubing to prevent heat loss. The type of floor construction (concrete slab, wood subfloor, etc.) will also influence the installation method.

Laying the Tubing:

The tubing must be laid out in a specific pattern and spacing to ensure even heat distribution. Common layouts include serpentine, spiral, and herringbone patterns. The tubing spacing is determined by factors such as the heat output required, the type of floor covering, and the tubing size.

Integrating with Other HVAC Systems:

In some cases, you may need to integrate the hydronic radiant floor heating system with other HVAC systems, such as forced-air systems or ventilation systems.Proper planning and coordination are necessary to ensure seamless integration and optimal efficiency.

Professional Installation vs. DIY:

While you can install a hydronic radiant floor heating system as a DIY project, experts generally recommend hiring a professional installer.Professional installers have the expertise and experience to ensure proper system design, installation, and commissioning, minimizing potential issues and ensuring optimal performance.

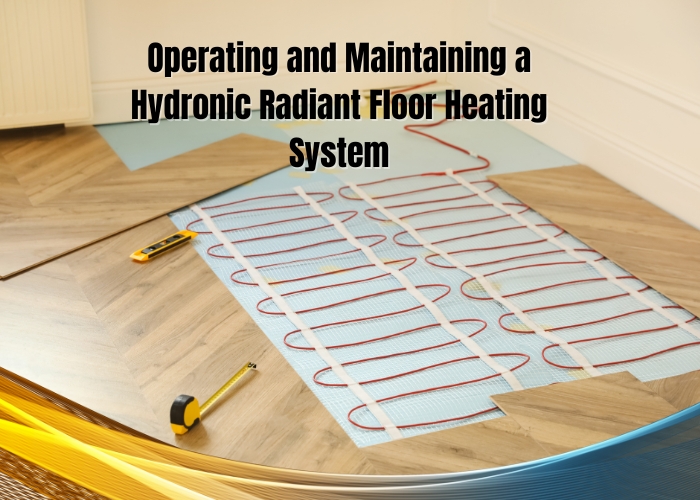

Operating and Maintaining a Hydronic Radiant Floor Heating System

Once installed, proper operation and maintenance are essential for maximizing the system’s efficiency, comfort, and lifespan. Here are some key considerations:

Setting and Adjusting Temperatures:

Thermostats or zone controls typically control hydronic radiant floor heating systems. Setting the appropriate temperatures for different areas or zones is crucial for maintaining comfort and energy efficiency.

Balancing the System:

To ensure even heat distribution, you need to properly balance the system. This involves adjusting the flow rates and water pressure in each tubing loop to account for variations in loop lengths or heat loads.

Regular Maintenance:

Regular maintenance tasks include bleeding air from the system, checking for leaks, and monitoring water quality. Periodic flushing or chemical treatment may be necessary to prevent scaling or corrosion in the tubing and components.

Energy-Saving Tips:

To maximize energy savings and efficiency, consider implementing strategies such as setting back temperatures when the space is unoccupied, installing programmable thermostats, and ensuring proper insulation and air sealing in the building envelope.

By following best practices for installation, operation, and maintenance, you can ensure that your hydronic radiant floor heating system provides comfortable environment for you.

Conclusion

Hydronic radiant floor heating systems offer unparalleled comfort, energy efficiency, and long-term value for homeowners and businesses alike. By considering key features such as energy efficiency, even heat distribution, compatibility with flooring types, smart controls, and reliability, one can select the best system to meet their needs. With top contenders like Uponor Wirsbo, Warmboard, Radiantec, and Rehau Raupanel leading the market, the journey to cozy, radiant warmth has never been more accessible.